About the Client

The client is a global leader in powertrain technology, headquartered in the European Union and built on the industrial expertise and legacy of one of the world’s leading automotive manufacturers. The company operates manufacturing plants and warehouses across multiple continents, spanning design, production, and distribution of powertrain systems.

The group maintains a strong culture of safety, health, and continuous improvement embedded across every level of operations. Its Health, Safety, and Environment (HSE) policies target zero work-related illnesses and accidents, supported by dedicated teams focused on injury prevention and ongoing improvement of workplace conditions.

Manual Assessments That Couldn’t Keep Up with Global Operations

The client had developed a custom ergonomics standard tailored specifically to their work domain — a rigorous framework that went beyond generic assessment methods. However, the process for executing these assessments remained manual, largely based on Excel spreadsheets and in-person observation by trained experts.

This created three operational bottlenecks:

Slow & Resource-Intensive

Each manual evaluation took approximately 120 minutes per task. With hundreds of workstations across multiple countries, the assessment backlog grew faster than experts could clear it.

Expert Travel Dependency

Ergonomics specialists needed to travel to each facility for on-site observation, generating ~$10,000 per expert per year in travel costs while limiting site coverage.

Ergonomics Deprioritized

With EHS teams stretched across safety audits, incident investigations, and compliance, ergonomic assessments were often the first activity deferred — leaving risk unquantified.

Digitizing a Custom Ergonomics Standard on the ErgoEdge AI Platform

The client selected ErgoEdge to transform their ergonomics program from a manual, Excel-driven process to an AI-powered digital platform — with a critical requirement: the ability to digitize and run their proprietary ergonomics standard alongside established open methods.

Custom Standard Integration

ErgoEdge digitized the client’s proprietary scoring methodology directly into the platform, running alongside RULA, REBA, and NIOSH in a single unified environment. No separate tools, no parallel spreadsheets.

Smartphone-Based Capture

Frontline supervisors recorded workers using standard smartphones and tablets. No wearable sensors, depth cameras, or additional hardware required. Videos uploaded to the secure cloud for AI processing.

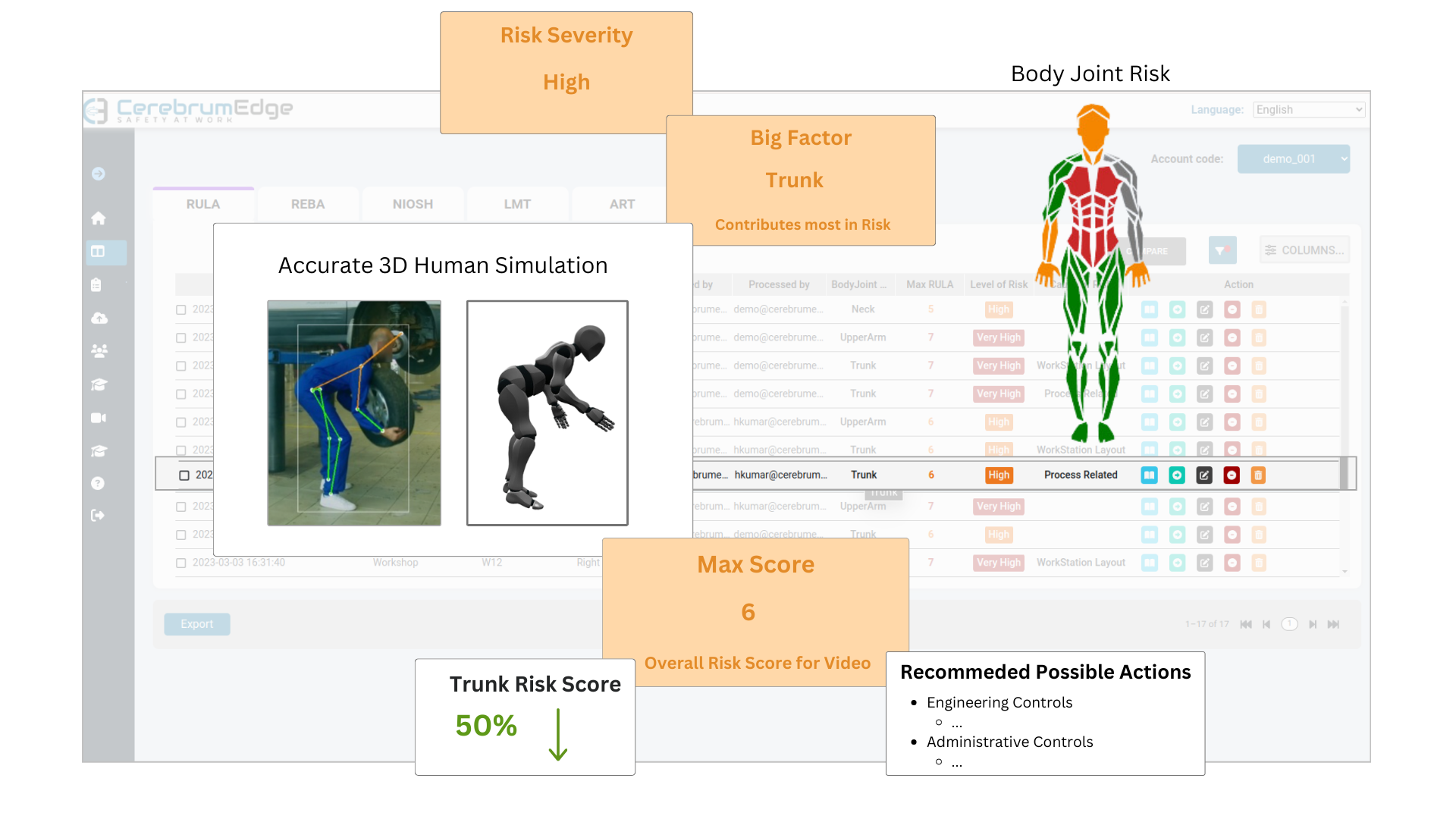

AI-Powered Analysis

Computer vision processed each video frame-by-frame, estimating 3D body joint positions and calculating risk scores with comprehensive reports including posture simulation and recommendations.

Remote Assessment Capability

Experts no longer needed to travel. Local teams captured video on-site, and specialists reviewed assessments, validated findings, and provided recommendations remotely from anywhere.

Deployed Across 5 Countries

10X Faster Assessments and Dramatically Expanded Coverage

10X Reduction in Assessment Time

Manual assessments that took ~120 minutes per task now take roughly 10 minutes, transforming ergonomic risk assessment from a bottleneck into a routine activity.

3–4X Increase in Task Coverage

EHS teams assessed three to four times more workstations, including previously unassessed lower-priority stations and remote sites.

~$10K Travel Cost Saved Per Expert/Year

Remote assessment eliminated expert travel. Local teams captured video on-site; specialists reviewed remotely, recovering significant travel budget.

Lower Overall Evaluation Cost

Faster assessments, eliminated travel, and reduced consultant dependency substantially lowered per-assessment cost. Ergonomics became economically scalable.

Streamlined Training & Onboarding

The digital platform enabled real-time demonstrations and interactive training for new EHS team members. Instead of shadowing senior ergonomists for weeks, new assessors could begin conducting assessments independently after a short onboarding session.

What Sets This Implementation Apart

Custom Ergonomics Standard Digitization

Most AI ergonomics platforms support standard methods like RULA, REBA, and NIOSH. What distinguishes this implementation is that ErgoEdge digitized the client’s proprietary ergonomics standard — one developed specifically for their work domain and refined over years of internal expertise.

The custom methodology was built directly into the platform, running alongside established open standards. This gave the client a unified assessment environment where:

“ErgoEdge enabled our team to cover three to four times more workstations while reducing each assessment from two hours to just ten minutes. We can now run both our custom standard and established methods on a single platform.”

Before & After ErgoEdge

| Metric | Before ErgoEdge | After ErgoEdge | Improvement |

|---|---|---|---|

| Assessment Time | ~120 minutes/task | ~10 minutes/task | 10X faster |

| Tasks Assessed | Baseline | 3–4X more | 3–4X coverage |

| Expert Travel Cost | ~$10,000/expert/year | Eliminated (remote) | ~$10K saved/expert |

| Evaluation Cost | High (manual + travel) | Substantially lower | Significant reduction |

| Training Approach | In-person shadowing | Digital real-time demos | Faster onboarding |

| Standards Supported | Custom only (Excel) | Custom + RULA, REBA, NIOSH | Single platform |